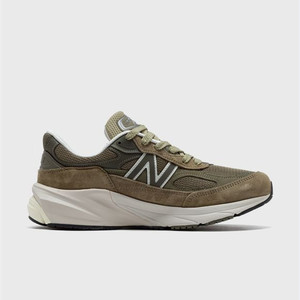

New Balance Sneaker Releases

Shop all New Balance sneaker releases

The well-known brand New Balance was founded as early as 1906 under the name "New Balance Arch Support Company" by 33-year-old immigrant William J. Riley in Boston. Initially, William J. Riley produced orthopaedic insoles until his successors produced the first running shoe "Trackster" in 1960.

At that time, the "Trackster" impressed with its wave-shaped sole and was produced in different widths. Even today, New Balance is one of the few brands that offers different widths. At that time, New Balance shoes were mainly known at the universities, where the sports clubs liked to use them — and not only at Boston University, but gradually all over the country. At that time, there was no big investment in marketing, but instead success came through word of mouth and local sporting goods fairs.

At that time, the "Trackster" impressed with its wave-shaped sole and was produced in different widths. Even today, New Balance is one of the few brands that offers different widths. At that time, New Balance shoes were mainly known at the universities, where the sports clubs liked to use them — and not only at Boston University, but gradually all over the country. At that time, there was no big investment in marketing, but instead success came through word of mouth and local sporting goods fairs.

New Balance Helps the Running Boom in the USA

It was not until the sale in 1972 to Jim Davis that the brand became internationally known. This was due in no small part to the running boom that spread through Boston and the entire USA.

Today, New Balance has more than 5,000 employees, and its shoes are sold in over 120 countries. In the past few years, the brand has experienced constant ups and downs. Among other things, this was due to the image problem after the New Balance sneakers gained popularity in the neo-Nazi scene. The reason for this is seen in the logo of the sneakers, because a large N is sewn onto the shoes. In order to get a grip on the situation, drastic measures had to be taken, and the sale of New Balance shoes was stopped in right-wing radical shops.

After these incidents, New Balance had to do a lot of convincing to get the normal stores to sell the brand's sneakers again and include them in their assortment. Fortunately, this also succeeded, especially through useful partnerships with stores like Solebox.

In recent years, the brand has boomed again, which we definitely don't begrudge New Balance after its problems. New Balance sneakers are now available in countless colours in almost every store. And rightly so, the retro sneaker hits the zeitgeist with its current designs. And the brand also celebrates great success in the runner scene.

Fun fact about New Balance sneakers

Steve Jobs was not only known for his black turtleneck jumper, but also for his grey New Balance sneakers.

The most popular New Balance models

When it comes to classic running shoes, there is no way around the popular New Balance 990. Launched in the 80s, the sneaker is characterised by its iconic silhouette, high-quality materials and craftsmanship. The 990 series has evolved over the years and includes various iterations such as the 990v2, 990v3, 990v4 and more.

Of course, the list of most popular NB sneakers cannot be without the coveted New Balance 550. This classic is arguably one of the brand's best-known and best-selling silhouettes. The lifestyle sneaker is known for its versatility, comfort and timeless design.

Another iconic running shoe is the New Balance 1906R, known for its cushioning and comfort. Again, the sneakerhead will find a timeless design.

If you talk about New Balance, you will also come across the "1500" model at some point. The well-known sneaker has excellent cushioning and support and is available in countless colourways.

From April 2020, fans will also find the New Balance 327 on retailers' shelves. Partner Casablanca made a grand debut and presented two impressive variants of the 327. Eye-catching details include a chunky sole with large studs and raised heels and toes.

One of New Balance's most popular sneakers is the New Balance 990v5. The latest iteration of the 990 range has attracted a lot of attention with its combination of comfort and style.

New Balance 1500 Orange "Made in England"

€229

New Balance 1500 Green Oasis "Made in England"

€229

New Balance 993 "Purple"

€240

New Balance 993 "Chive"

€240

New Balance FuelCell Rebel v4 "Linen"

€160

New Balance WRPD Runner "Licorice"

€179

Jaden Smith x New Balance MSFTSrep 0.01 "Grey"

€130

Jaden Smith x New Balance MSFTSrep 0.01 "Panda"

€130

New Balance Kawhi 4 "Transcend Reality"

€170

New Balance 990v6 "True Camo"

€240

New Balance 1000 SL "Silver Metallic"

€169

New Balance Numeric 480 "Forest Green"

€110

New Balance Numeric 480 "Purple"

€110

Joe Freshgoods x New Balance 1000

€190

New Balance 991v2 "Cool Grey"

€249

Auralee x New Balance WRPD Runner "Navy"

€180

Auralee x New Balance WRPD Runner "Taupe"

€180

JJJJound x New Balance 2002R Gore-Tex "Charcoal"

€238

JJJJound x New Balance 2002R Gore-Tex "Pine"

€198

Snow Peak x New Balance Niobium C_3

Joe Freshgoods x New Balance 990v4 "Marshmallow"

€289

.jpg)

Joe Freshgoods x New Balance 990v4 "Peat"

€330

District Vision x New Balance Fresh Foam More Trail "Falcon"

€253

District Vision x New Balance Fresh Foam More Trail "Jet Stream"

€249

Patta x New Balance 991v2 "Pickled Beet"

€233

Levis x New Balance 580 "Dark Grey"

€115

Levis x New Balance 580 "Beige"

€121

New Balance 1906D Protection Pack "Silver"

€99

New Balance 1906D Protection Pack "Eclipse"

€116

Tokyo Design Studios x New Balance 610S "Outerspace"

€154

Tokyo Design Studios x New Balance 610S "Concrete"

€127

KITH x New Balance 990v6 "Madison Square Garden"

€310

.jpg)

The Apartment x New Balance 576 "Antique White"

€674

The Apartment x New Balance 576 "Bitter Chocolate"

€432

Aimé Leon Dore x New Balance 550 "Dawn Glow"

€96

.jpg)

Aimé Leon Dore x New Balance 650 "Classic Pine

€184

.jpg)

Carhartt WIP x New Balance 990v6 "Sculpture Center"

€186

Stone Island x New Balance 991v2 "Black Olive"

€241

Concepts x New Balance 998 "C-Note"

€146

.jpg)

Jaden Smith x New Balance MSFTSrep 0.01 "White"

€109

Auralee x New Balance 1906R "Flint Stone"

€186

Auralee x New Balance 1906R "Bone White"

€167

CAYL x New Balance 610 "Covert Green"

€149

CAYL x New Balance Fresh Foam X More Trail V3 "Shadow Grey"

€161

.jpg)

Aimé Leon Dore x New Balance 550 "True Brown"

€114

.jpg)

Aimé Leon Dore x New Balance 550 "Warm Sand"

€104

thisisneverthat x New Balance 550 "Brown"

€118

thisisneverthat x New Balance 550 "Dark Green"

€140